SLB has announced a significant breakthrough in the sustainable production of lithium at scale, unveiling successful results from its demonstration plant in Clayton Valley, Nevada. The new approach integrates advanced direct lithium extraction (DLE) and conversion technologies, with the potential to transform lithium production by significantly reducing environmental impacts while speeding up the process by 500 times compared to conventional methods.

The proprietary system developed by SLB offers a more sustainable way to produce lithium, a critical resource for the rapidly growing electrification economy. The company claims that its integrated technology solution, which combines subsurface expertise with surface engineering, can produce lithium with a 96% recovery rate from brine while using far less land, water, and chemical reagents than traditional methods.

Sustainable and Scalable

Lithium is a crucial element in the manufacturing of batteries for electric vehicles (EVs), smartphones, and renewable energy storage systems. The rising demand for lithium products has put significant pressure on traditional extraction methods, which are known to be resource-intensive and environmentally harmful.

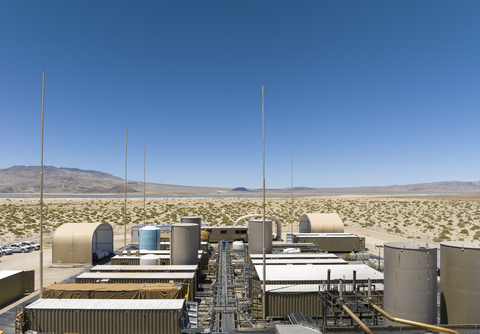

At its Clayton Valley demonstration plant, SLB has showcased a groundbreaking technology that not only accelerates lithium production but also makes the process more sustainable. Unlike conventional methods, which involve large evaporation ponds and can take up to 18 months to produce lithium, SLB’s technology delivers results within hours.

“Lithium is a key enabler of electrification, so we must find ways to accelerate its production without adversely affecting the environment,” said Gavin Rennick, president of SLB’s New Energy business. “Our demonstration plant in Clayton Valley proves our unique integrated approach to produce scalable quantities of lithium in the fastest, most economical, and sustainable way for today’s market.”

Environmental Advantages

One of the most critical advantages of SLB’s process is its drastically reduced environmental footprint. The plant operates at approximately one-tenth the size of a conventional commercial-scale lithium extraction facility, while using just 10% of the land typically required. This reduction in land use is particularly significant given that traditional lithium production methods, such as evaporation, require extensive land and water resources, often resulting in biodiversity loss and environmental degradation.

SLB’s method also addresses the water consumption issue. Traditional evaporation techniques can result in massive water loss, leaving behind salt, underground minerals, and used chemicals that damage local ecosystems. In contrast, SLB’s approach recycles the spent brine, returning it to its source after the lithium has been processed and separated. This innovation not only conserves water but also minimises the environmental impact on the surrounding area.

From Extraction to Conversion in Hours

SLB’s solution represents a complete, end-to-end process that extracts lithium from brine, purifies it, and converts it into high-purity lithium carbonate or hydroxide, depending on market needs. The entire process takes just hours, a remarkable improvement compared to the months required by traditional methods.

The company’s system is highly flexible, capable of adjusting production to meet demand for different lithium products. Lithium is commercially sold in several forms: lithium chloride, used to produce lithium metal; lithium carbonate, used in smartphones and short-range EVs; and lithium hydroxide, a key component in long-range EV batteries. SLB’s technology can be tailored to produce any of these products efficiently.

Industry Milestone

In proving this technology at its pilot plant, SLB has met crucial technical milestones, positioning itself to take full advantage of its partnership with Pure Energy Minerals Ltd. Through an earn-in agreement, SLB may acquire a 100% ownership interest in the Clayton Valley Project, a strategic move that could further solidify its role as a leader in sustainable lithium production.

The potential for this new method to be implemented at commercial scale could be a game-changer for the lithium industry. As the world shifts towards greener technologies, the demand for lithium is expected to rise dramatically, particularly in the electric vehicle sector. SLB’s innovation offers a way to meet this growing demand while minimising the environmental impact typically associated with lithium production.

Looking Ahead

The success of SLB’s Clayton Valley plant marks a significant step forward in the company’s mission to revolutionise lithium production. By cutting the time, cost, and environmental toll of the extraction process, SLB is paving the way for more sustainable practices in the energy transition.

As Rennick pointed out, the next phase will focus on scaling up this technology for commercial use. “This accelerates deployment of viable commercial-scale facilities for high-quality lithium products that are the backbone of our electrification economy,” he said.

With its sights set on broader commercialisation, SLB’s demonstration in Nevada may very well set a new standard for the lithium industry—one that prioritises both speed and sustainability in delivering the vital resources needed for a cleaner, electrified future. Find out more at slb.com.